Technology refresh

technology refresh

We provide production line technology refresh services. These will include the current line assessment (by studying existing documentation as well as on site visit), identification of components in need of an upgrade, preparation of budget and upgrade plan. The technology refresh project will include:

- Requirements gathering – including final product spec improvements

- Automation component replacements (valves, driving train, sensors, etc.)

- Electrical wiring replacements including components delivery

- Automation control system delivery including integration of such a system into the customer environment

from our realizations

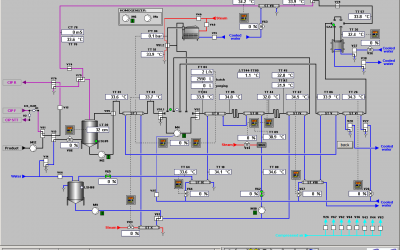

UHT food processing control system including sterile tank for end user Awal Dairy in Bahrain (2017)

Complete delivery and implementation of new control system including electrical distribution, pneumatic components and metering systems. Control system is implemented in Simatic S7 framework and visualization in SW InTouch.

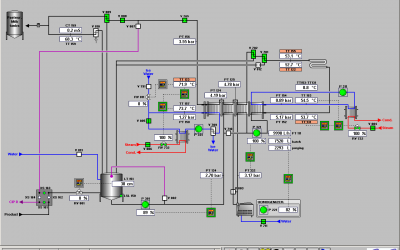

Turnkey delivery of milk pasteurization system for Awal Dairy – Bahrain (2019)

Technology design and turnkey delivery of pasteurization system automation components. The existing system failed US Navy audit and needed complete refurbishment. The production line was stopped for only 7 days when the electrical installation, automation components and commissioning were executed.

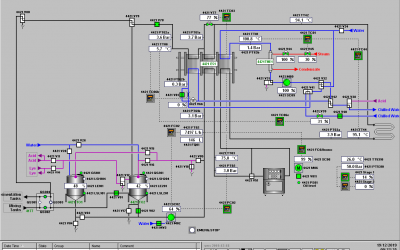

Control and Visualization of yogurt pasteurization component- Friesland-Romania (2019)

Technology design and control of reused pasteurization production line component. The pasteurizer control was integrated into the full Friesland Romania factory production line control system. The control system was implemented in Siemens PLC, visualization in SW InTouch.

Have you any question or are you interested in our offer?

Please use the form below or call +420 606 957 691, +420 774 112 848